Table of Contents:

Without question. All bows only work with a string. It tensions the bow and shoots the arrow away. But what is important, if you now want to get a string, what do you need to consider? In principle, it is said that the string needs to be strong and tear-resistant. But if we also want it to deliver the arrow as far as possible, then it should also be light. Because light means less resistance, ergo it is faster. If the string is faster, so is the arrow. So far so good.

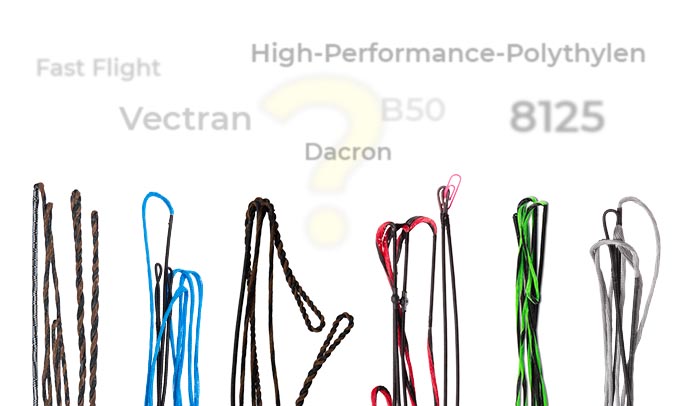

If you take a look at the string section (recurve, compound, traditional), you will quickly find what you are looking for. There are not countless string (yarn) manufacturers, but enough to be at a loss, especially as a beginner. On the one hand there are brand names, on the other hand there are material names, which could cause confusion. But don’t worry, none of this is hocus-pocus. And if you read a bit more about it, it’s even quite logical. So here’s our overview for now.

Components of a String

The structure of a string is actually quite simple. One has to distinguish between the yarn and a string. The string consists of string yarn and the serving. In our shop you can find all of them: different kinds of strings, ready to use, as well as all the components to make a string on your own. If you want to make your own string, you only need to buy the desired string yarn and serving material. On a so-called string jig (with the help of a serving tool) you can make a functional string yourself.

While the string yarn defines the length and thickness of the string, the serving stabilizes and seals the string ends. These would be, on the one hand, the center serving – the place where the arrows are nocked – on the other hand, the end servings, which close the string yarn and, if necessary, the end loops.

String Models Sorted by Material:

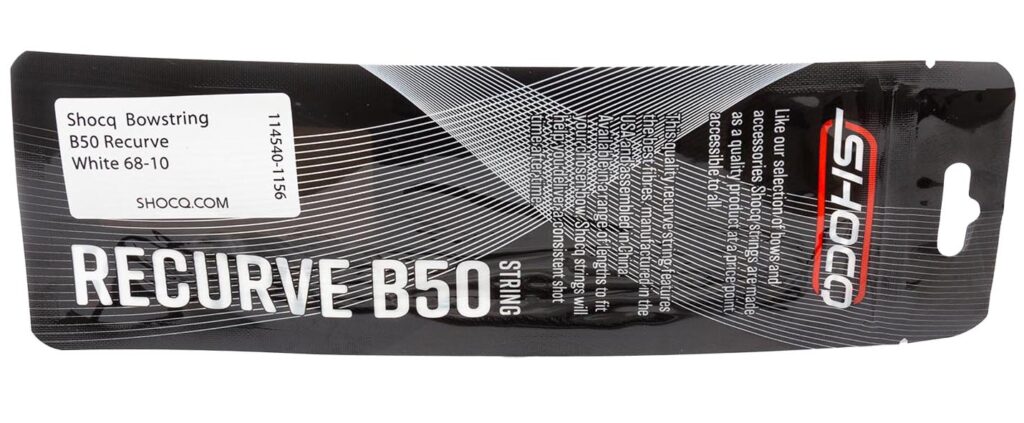

Polyester

B50 / B55 / Dacron: If you spend a few minutes browsing through the entire string assortment, you will quickly come across the designations B50, B55 or Dacron. These product names stand for string yarns made of polyester. While B50 is a product of the company Brownell & Co., B55 in turn stands for that of the company BCY. However, both refer to the same string material composition. (Yes, we think so too: the naming in both cases has turned out very creatively!). Dacron is another brand name in this field, which also stands for string yarn made of polyester by Dupont.

B50 / B55 / Dacron strings are known for their lightness and very high durability, but are usually slower than Fast Flight strings.

HPPE (High-Performance-Polythylen)

Fast-Flight (FF): This brand name does not hide any hidden messages. With „Fast Flight“ / abbreviated „FF“ the company Brownell named its type of strings made of HPPE (high-performance polyethylene), which makes the string much lighter and the fibers more tear-resistant than, for example, Dacron. There was a time when the string manufacturer FLEX used the name „Fast Flight Plus“ / „FF+“. We have not been able to find out what the plus / + in their FF actually means, especially since the terms FF and FF+ are always used interchangeably in the archery scene (in which we are at least). Therefore, we assume that FF+ is also exactly the same as FF and the „plus“ was simply introduced for some marketing reason. But if you have any other useful information, feel free to enlighten us in the comments!

UHMWPE (Ultra-High-Molecular-Weight-Polythylen)

8125: This number sequence is used by string manufacturers to designate a modern string yarn made of SK75 Dyneema. Dyneema is the brand name of DSM for its UHMWPE fiber (Ultra High Molecular Weight Polyethylene). SK75 in turn describes a quality grade of Dyneema.

For a short time, BCY marketed a string yarn with the slightly modified name: 8125G. This contained a very small proportion of Gore fibers, which were supposed to improve abrasion resistance and somewhat reduce shooting noise. Apparently the manufacturer wasn’t entirely convinced and stopped production after a short time. BCY itself explained that they discontinued the Gore-containing string yarn „because the Gore fiber didn’t add to or improve the performance of the 8125.“

8190: A similar story to 8125G also experienced the model 8190 by BCY. This number sequence designates another modern string yarn made of SK90 Dyneema and GORE fibers. As already mentioned in 8125, the Gore content is supposed to provide an optimization of the string attributes, but a factual added value of Gore fibers in a string remained missing, which is why the 8190 is also no longer available.

452X: While Gore apparently has not proven itself for BCY, a proportion of Vectran, on the other hand, has turned out much more successful. The string yarn 452X consists of 67% SK75 Dyneema and 33% Vectran and has the effect that the string remains completely creep-free. This is particularly important for compound bows.

X99: The X99 by BCY also refers to string yarn made of 80% SK75 Dyneema and 20% Vectran content. Here it can be assumed that the ratio shift also plays with the „no-creep“ property.

Frequently Occurring Technical Terms Briefly Explained

Flemish splice: Describes a way of forming the end of a string into a loop without knots by a braiding method. This type of string winding is used especially in traditional archery, or traditional bows.

The Flemish splice can actually be recognized well by the „braided structure“ of the end loops, or the complete chord.

This way of making strings would have to be seen in contrast to the endless serving. In this process, the string yarn is wound several times in the desired length and then „sealed“ by another serving material.

Even though the overall string color can be polychrome, it is not „braided“ in that sense, but more often twisted and wrapped at the ends. There are also strings where the loops are spared from the serving.

Stretch:

This word in relation to strings describes a certain degree of stretching of the whole string, or the string yarn, during drawing. The decisive factor is the fact that this stretching is reversible.

Creep:

This word is to be seen as the opposite of „stretching“. It describes a rather undesirable behavior of a string, or string yarn. The string stretches in an irreversible manner when force is executed.

Gore: Is probably known to most people in particular for functional clothing and footwear. Gore is the trade name of W. L. Gore & Associates for a microporous membrane (wet barrier membrane) made of polytetrafluoroethylene (ePTFE) that is windproof, waterproof, but permeable to water vapor and thus breathable. Gore, blended into strings, has virtually no effect on stretch and creep; it was used for a time in string production to bring extremely thin string material to a strength similar to Fast Flight. However, this composition does not seem to have proven successful, especially since Gore-added strings are no longer available on the market

Vectran: Vectran is an LPC aramid (high-strength synthetic fibers with increased temperature resistance (PPTA) and melt-spinnable polyaromatic fibers (LPC)) and has no stretch and no creep when the string is pulled out. However, Vectran is only used in combination with other materials, otherwise the string could be too hard and thus break. A percentage of Vectran is included in the most modern Fast Flight and Dyneema strings to make them thinner and more powerful. BCY’s string model 452X, for example, illustrates this synthesis of synthetic materials: it consists of 2/3 8125 (Dyneema SK75) and 1/3 Vectran.

Which String is Suitable for Which bow?

Now the question: „Which string is suitable for my bow?“ That depends very much on what kind of bow you have. For a general overview, however, we have also listed generally valid characteristics that would not be wrong even without any manufacturer information.

Traditional Bows

Dacron is e.g. for wooden bows or longbows the most used string material and in moments of doubt, definitely never the wrong choice. It is stable and durable, but also stretches with each shot, for example, more than a FF string and is therefore particularly suitable for traditional bows. In fact, Dacron allows the usually simple construction of traditional bows not to break due to the abrupt stopping of the string. Dacron therefore unfortunately has the highest inherent mass and stretch of all yarns and is therefore by far the slowest string material.

However, there are now also more efficient bows in the traditional range. Here, mainly modern composite materials are used and the structure is adapted to that of the Olympic recurve. In such a case, one could switch to FF or even 8125 with a clear conscience.

We have compiled the most common strings for traditional bows here:

Strings for Traditional bowsOlympischer Recurve

In theory, you could try any string model on the Olympic recurve without risking damaging the bow. Practically, however, some things make little sense. With an Olympic recurve, it is actually unnecessary to ever use a Dacron string. The bows are usually modern and much more capable, respectively more durable than for example many traditional bows. Since FF yarns, for example, are faster than Dacron, they also put much more strain on the bow when shooting, even though the draw weight remains the same with any string material. If in the instructions for the bow, for example, a FF suitability is confirmed, then one should always use FF, or use the more efficient material. After all, why should you give away any efficiency of the bow, which you actually (so bitterly) need?

In the European area, one hears also more frequently that even modern string yarns such as 8125 are often preferred over FF. But we have also heard that in Asian regions, or more precisely among Korean archers, FF is preferred because it is more forgiving than 8125.

As you can see, your own experience and individual perception play a decisive role here. Therefore, it may be worthwhile to shoot with different materials at competition distances and to observe the results, as well as to record your own impressions.

At this point, for safety’s sake, we would like to point out the unsuitability of strings containing Vectran for the Olympic recurve. Park Kyung Rae, Chairman of W&W apparently said explicitly at a seminar that you should not use low-stretch Vectran strings on your limbs. George Tekmitchov, Senior Recurve Engineer and International Staff Manager at Hoyt, seems to have said the same thing about Hoyt limbs.

In case of doubt, please contact the manufacturer.

We have strings for recurve bows compiled here:

Strings for RecurveCompound

Materials with a high proportion of Vectran (especially 452X) are only intended for compound bows (this is also recommended by the manufacturers), for they do not have any creep. You have to imagine for a moment: Compound bows remain strung non-stop for several years, if the string would give in any way and deform, it would be fatal. For this reason, no FF, let alone Dacron strings are used for a compound bow. To be on the safe side, some string manufacturers also like to use the adjective „no-creep“.

Fact: For compound bows, in addition to the string, there are also cables, which are necessary for the characteristic lever mechanism. You can buy them as a set, as well as separately.

We have strings and cables for compound bows compiled here:

Strings & Cables for Compound